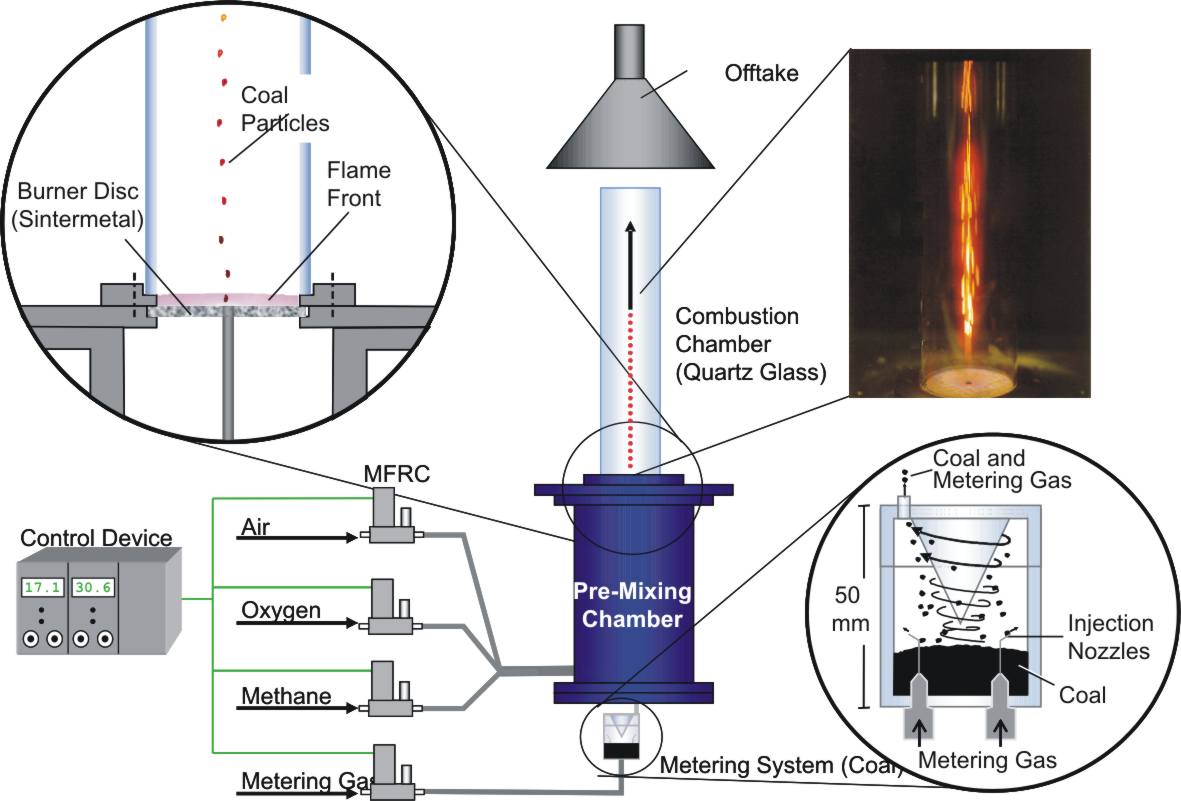

Flat Flame Burner

The department of Energy Plant Technology developed a pre-mixing burner to analyse the firing and combusting behaviour of carbon dust particles under real conditions. It provides the possibility to track the coal conversion during the whole combustion process.

The Experimental-Setup is composed of the following components:

- mass flow rate control device

- carbon dust metering

- mixing chamber including sinter metal disc

- quartz glass tube

- waste gas offtake

The oxidizer and the fuel are mixed up in the pre-mixing chamber of the AFFB with electronic mass-flow rate controllers. The ignitable mixture, in general methane and air, passes the sintermetal disc and flows in the attached quartz glass tube. As soon the mixture is ignited, a homogeneous flame front is generated on the top of the sinter metal disc due to its geometry. The sinter metal disc is operating as a flame stabilizer. Thus, a backfire into the pre-mixing chamber can be prevented.

The coal dust particles are injected in the heated combustion chamber through a small borehole via a custom-built metering System. The coal doser is composed of a small cylindric pot, in which small nitrogen flow rates are injected via four hypodermic needles. Thus, an upward directed eddy is formed, which transports the coal particles to the combustion chamber.

The quartz glass tube separates the hot stream of combustion gases from the surrounding atmosphere and guarantees a well defined temperature field. In addition the tube directs the combustion gas in a single direction and provides optical access during the whole process, from firing to complete combusting.